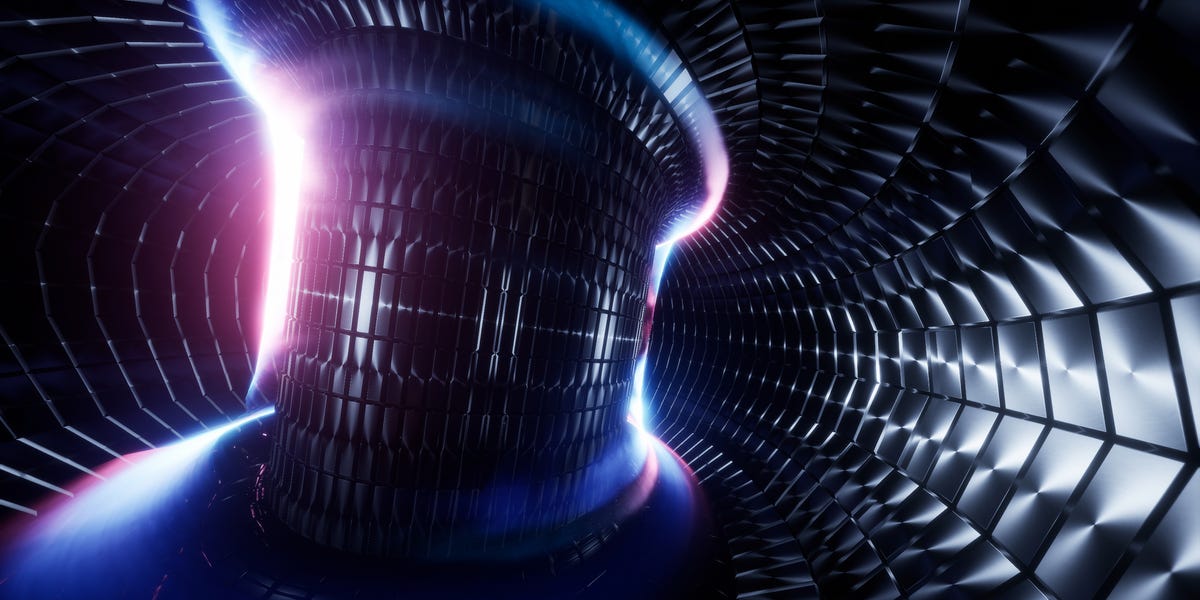

If a tokamak is a “bottled star,” then the divertor is the part of the bottle that gets yelled at the most.

It’s the exhaust systemwhere hot particles and heat (that the magnets can’t perfectly corral) are supposed to go politely.

The problem is that tokamak exhaust is not polite. It arrives like a firehose made of lightning.

For decades, one of the biggest headaches in commercial-scale fusion has been a deceptively unglamorous question:

Where does the escaping plasma energy actually land?

If too much heat concentrates on too small a patch of wall, the reactor’s plasma-facing components can wear out fast,

forcing downtime, repairs, and replacement operations that are… not exactly “plug-and-play.”

That’s why a “new plasma escape plan” (really: a new understanding of the escape routes at the plasma’s edge)

is such a big deal. Recent high-fidelity simulations suggest the exhaust heat and particles may spread over a

larger area than older models predictedessentially widening the “strike zone” where electrons connect the core’s

edge to the divertor. It doesn’t make exhaust vanish, but it can make the heat less concentrated,

which is the difference between “durable machine” and “expensive maintenance treadmill.”

Why plasma exhaust is fusion’s make-or-break “boring problem”

Fusion headlines usually focus on big, cinematic milestones: higher temperatures, longer pulses, better confinement,

and the holy-grail metric Q (fusion energy out compared to heating energy in). But even if you win those battles,

you still have to keep the machine alive. And the survival game is played at the edge of the plasma.

In a tokamak, the “main plasma” is magnetically confined, but not perfectly. A thin outer layeroften described with

terms like pedestal, scrape-off layer (SOL), and divertor plasmais where turbulence,

electric fields, and magnetic geometry decide how heat and particles escape. Think of it like weather at the

boundary of a hurricane: the storm’s structure matters, but the chaotic edges determine where the damage actually hits.

Here’s the commercial-scale problem in plain language:

if the exhaust heat arrives in a super narrow band, materials face punishing heat fluxhigh enough to challenge even

very tough armor materials. If the exhaust can be distributed across a wider surface, the same total power becomes

much more manageable.

Key takeaway (no lab coat required)

- Narrow strike zone = extreme localized heating, faster wear, more downtime.

- Wider strike zone = lower peak heat flux, better durability, more reactor uptime.

- Better edge physics = better engineering margins (and fewer “surprise” wall interactions).

Tokamak 101: magnets, a donut, and a plasma that wants to leave

Tokamaks confine plasma with magnetic fields shaped like nested surfaceslike onion layers made of invisible force.

Fusion-grade plasmas reach temperatures on the order of 150 million °C, which is far hotter than the Sun’s core.

(Yes, that sentence is real. And yes, it sounds like science fiction.)

The point of the magnetic geometry is to keep most of that energy away from the walls. But heat and particles still

leak outwardespecially along magnetic field lines that guide charged particles like rails guide a train.

The regions where field lines intersect material surfaces become the “landing zones” for exhaust.

If you’ve heard tokamak people say “the edge is hard,” this is why: core confinement is already challenging,

but edge physics includes turbulence, intermittent bursts, impurities, neutral particles, and complex geometry near the

X-point (where the magnetic separatrix forms). It’s like trying to do precision engineering in a wind tunnel full of confetti.

Meet the divertor: the reactor’s exhaust pipe (with a tough job description)

The divertor is designed to do three jobs at once:

remove heat, remove particles (“ash” and fuel that didn’t fuse), and do it without contaminating the core plasma.

It’s a balancing actlike venting a furnace while keeping the living room spotless.

Heat flux isn’t just “hot”it’s concentrated hot

Engineers don’t only worry about temperature; they worry about heat fluxhow much power hits each square meter.

In next-step devices, the divertor has to handle heat loads on the order of 10–20 MW per square meter

in relevant operating scenarios. That’s why tokamaks use robust plasma-facing materials (often tungsten-based armor),

elaborate cooling, and careful magnetic shaping.

Now add the scary part: older expectations suggested that the hottest exhaust could concentrate in a very narrow band.

A narrow band means extreme peak loading, which can accelerate erosion, cracking, and other forms of damageeven

if the overall reactor is “working.”

The “new plasma escape plan”: what changed in the physics story

The new work centers on a boundary that sounds tidy on paper:

the last confinement surface (often discussed as the “last closed flux surface”).

In simplified pictures, it’s a clean dividing line: inside = confined plasma, outside = scrape-off layer and divertor region.

Reality is messier. Advanced simulations show that turbulence can disturb that boundary so strongly that a “perfectly clean”

last surface effectively stops being perfectly clean. Instead, field-line connections become complicated, and particlesespecially

electronsfind additional pathways that connect edge regions to the divertor.

Why electrons matter so much

Electrons are light and fast, and in magnetized plasmas they play an outsized role in energy transport along field lines.

Earlier modeling already suggested turbulence could widen the heat-flux footprint dramatically.

The newer insight goes further: the magnetic boundary itself can be significantly “ruffled” by turbulence,

opening up extra connection channels that broaden where the heat lands.

Homoclinic tangles: the least cozy word for a very real effect

One of the most memorable terms tied to this work is homoclinic tangles.

Despite sounding like a villain from a math-themed superhero movie, it’s a real concept from nonlinear dynamics:

when trajectories (or, here, magnetic field-line structures) become chaotic and intertwined.

In the tokamak edge, this kind of chaos means the “separatrix” region isn’t a neat border.

Instead, turbulent electromagnetic fluctuations can create a complex web of connection paths.

Translation: exhaust electrons can reach the divertor across a broader region than predicted by simpler models.

The simulation angle: why high-performance computing is doing heavy lifting here

This isn’t a back-of-the-envelope update. These conclusions are driven by detailed, first-principles-style modeling

using advanced plasma simulation tools (including gyrokinetic approaches designed for edge physics).

The computational challenge is enormous because the edge involves multiple scales at once:

fast electrons, slower ions, turbulent structures, and geometry near the divertor and X-point.

The practical outcome is the part engineers care about:

a wider heat strike zone than previously expected in reactor-scale conditions.

A wider footprint reduces the peak heat stress on the divertor surfaceexactly what future reactors need.

Why this matters for ITER-scale machines and beyond

When you scale up to a reactor-sized tokamak, everything gets harder: more power, more particle flux, more operational demands,

and less tolerance for frequent component replacement. If peak exhaust loads can be reduced (or at least distributed)

without sacrificing performance, that’s a major de-risking step.

Less “narrow-band panic,” more design breathing room

A wider strike zone doesn’t magically solve heat exhaust. The divertor still needs robust materials, cooling,

and operational strategies. But it can shift the engineering conversation from “this might be impossible” to

“this is difficult but designable.”

It plays well with other exhaust strategies

Fusion researchers don’t rely on a single trick. Instead, they stack strategies like a very nervous wedding cake:

each layer helps prevent collapse. The new “escape plan” insight complements approaches such as:

- Impurity seeding (adding carefully chosen impurities so part of the exhaust energy radiates away before hitting the wall).

- Divertor detachment (a regime where plasma near the divertor cools and recombines, reducing direct heat loads).

- Magnetic geometry tweaks (advanced divertors that increase the wetted area or change connection lengths).

- Control systems (actively managing where and how exhaust lands, including real-time monitoring and response).

The big win is synergy: if turbulence-driven broadening helps spread heat, then radiative cooling and detachment can reduce

how much power remains to be handled by solid surfaces. Together, they can move the divertor challenge from “showstopper”

to “engineering problem with a plan.”

How the new insight fits into the broader “exhaust toolbox”

1) Strike-point sweeping: don’t hold the blowtorch still

One straightforward idea is to move the strike point around so the divertor doesn’t get cooked in the same spot continuously.

Think of it like moving a heat gun while stripping paint: keep the tool moving so one patch doesn’t char.

Some reactor concepts incorporate deliberate strike-point motion as part of their baseline exhaust strategy.

2) Advanced divertor shapes: snowflake, Super-X, and friends

Engineers and physicists have explored “advanced magnetic divertor” configurations that modify the X-point geometry

and field-line connection lengths. Names like snowflake divertor and Super-X divertor are not marketing gimmicks;

they describe specific magnetic topologies that can increase the area wetted by exhaust and help reduce peak loading.

3) Detachment: the art of cooling the exhaust before it hits

Detachment aims to reduce heat loads by making the divertor plasma cooler and denser near the target surfaces,

so energy is dissipated through radiation and atomic processes rather than slamming into tungsten like a cosmic hammer.

The trick is maintaining core performance while keeping the divertor in a safe, detached (or partially detached) state.

4) Smarter monitoring and control: faster than “uh-oh”

Modern fusion programs increasingly lean on rapid modeling, machine learning tools, and improved diagnostics

to predict and manage heat loads. The better you understand where heat wants to go, the better you can steer it

or at least stop it from picking the worst possible place to land.

What still needs to happen before this becomes “reactor reality”

Fusion is famous for being both real and stubborn. A simulation-driven insight is valuable, but next steps matter:

- Cross-machine validation: compare predictions against measurements in multiple tokamaks and operating regimes.

- Better edge diagnostics: measure heat-flux widths, turbulence structures, and boundary perturbations with higher fidelity.

- Control integration: use the physics insight to improve real-time exhaust management strategies.

- Engineering translation: convert “wider strike zone” into concrete design margins for divertor components and cooling systems.

It’s also important to be honest: exhaust spreading doesn’t erase the need for robust materials, neutron-resistant structures,

and maintainable reactor architecture. But it can reduce the severity of one of the nastiest constraints on tokamak design:

the fear that exhaust power must land in an ultra-thin strip no material can tolerate for long.

Experiences from the edge (the extra )

If you want to understand why fusion people get so animated about divertors, imagine you’re building a rocket engine

that runs perfectly… except the exhaust plume sometimes decides to focus itself into a laser pointer aimed at your engine wall.

That’s the emotional vibe of plasma exhaust work: the core plasma can look gorgeous on the plots, the confinement can be strong,

and then the boundary physics reminds everyone that the universe enjoys pranks.

Researchers who live in the “edge and divertor world” often describe it as an exercise in humility. The core is where you try to

create the conditions for fusion; the edge is where you negotiate with reality. You can feel it in the way teams plan experiments:

not just “How do we get higher performance?” but “How do we get higher performance without torching the exhaust plates?”

In control rooms, you’ll hear a mix of technical talk and gallows humorbecause the only thing hotter than the plasma is the

collective anxiety when heat loads spike.

The day-to-day experience is also surprisingly tactile, even though the plasma never touches anyone directly. Engineers obsess over

cooling channels, surface temperatures, and allowable thermal gradients. Physicists obsess over heat-flux width, turbulence spectra,

and whether a change in magnetic shape will redistribute power the way they hope. Diagnostics specialists obsess over whether the

instruments are seeing the truthor a very convincing illusion created by geometry and signal processing.

And then there’s the human “pattern recognition” side. Over time, teams learn the personality of a machine: which scenarios tend to

produce a narrow strike zone, which operating modes drift toward detachment, and which combinations of fueling and magnetic shape

quietly raise the risk of ugly wall interactions. It’s like learning a complicated musical instrument that occasionally spits sparks

when you hit the wrong chord.

That’s why a result suggesting “the exhaust footprint may be broader than we feared” hits differently when you’ve spent years

treating narrow heat loads as a looming existential threat. It feels like finding out the monster under the bed is still there,

but it’s smallerand it’s standing farther away from your toes. Nobody on a fusion team hears that and says, “Cool, we’re done.”

They say, “Greatnow let’s measure it, validate it, and design around it.”

In practice, “design around it” means better alignment between modeling and operations. It means using simulations not as a

post-mortem (“why did the heat hit there?”) but as a planning tool (“if we run this scenario, where will the heat go?”).

It also means expanding the conversation beyond one magic solution. A wider heat-flux footprint can combine with impurity seeding,

detachment control, and advanced divertor shapes. The lived experience of fusion R&D is that progress rarely comes from one

heroic breakthrough; it comes from stacking improvements until the impossible becomes merely difficult.

And if you ever wonder why people in fusion get so attached to phrases like “edge physics,” it’s because the edge decides whether

your star-in-a-bottle is a beautiful science experimentor an extremely expensive toaster that keeps burning the same slice of bread.

The new plasma escape plan doesn’t guarantee commercial fusion, but it does something just as important: it makes the path forward

look less like a cliff and more like a steep hill with switchbacks.

Conclusion

Fusion reactors don’t just need hot, well-confined plasmasthey need a safe, reliable way to handle what escapes.

The new plasma escape plan reframes a major worry: rather than exhaust heat focusing into an impossibly narrow stripe,

turbulence and boundary complexity may broaden the strike zone, reducing peak loading on divertor surfaces.

This doesn’t eliminate the divertor challenge, but it strengthens the engineering case for tokamaks by improving design margins

and complementing other exhaust strategies like detachment and radiative cooling. In the slow, steady march toward practical fusion,

a little extra “wetted area” can translate into a lot more confidence.