Quick safety note: Generators involve fuel, high heat, and electricityso testing can be risky. If you’re not trained (or you’re under 18), treat this as a “what to ask for / what to confirm” checklist and have a qualified adult or licensed technician perform the hands-on work. Always follow your manufacturer’s manual and local electrical codes.

A generator is like that friend who says, “Call me if you need anything!”and then you don’t hear from them for two years. The day the power goes out is a bad time to discover your “friend” won’t start, your extension cords are sketchy, or your setup accidentally sends power back into the neighborhood like you’re auditioning for a superhero origin story.

This guide walks you through a practical, safety-first way to test a generator in 15 steps. The goal isn’t to do fancy engineering tricks. The goal is simple: prove your generator is readyand prove it without creating a carbon monoxide problem, an electrical hazard, or an expensive repair bill.

Before You Test: Know What Kind of Generator You Have

Portable generator

Typically gasoline-powered (sometimes propane or dual-fuel), moved into position when needed, and used with extension cords or (safest) a properly installed transfer switch/interlock. Portable units are the ones most associated with carbon monoxide tragedies and unsafe “backfeeding” mistakes.

Home standby generator

Permanently installed, often runs on natural gas or propane, and usually has an automatic transfer switch. Many standby units self-test weekly (often called an “exercise” cycle), but they still need periodic inspection and professional maintenance.

Inverter generator

A type of portable generator that typically produces “cleaner” power for sensitive electronics. Still has the same big safety issues: exhaust, fuel, and electrical connections.

The Big Three Hazards (And Why Testing Is Worth It)

- Carbon monoxide (CO): You can’t see it or smell it, and it can overwhelm people fast. Testing a generator in the wrong location is dangerous.

- Electrical shock / electrocution: Wet conditions, damaged cords, and incorrect connections increase risk.

- Backfeeding: Feeding generator power into home wiring without proper equipment can energize utility lines and endanger workersand can also damage homes and appliances.

Now, here’s the test plan.

How to Test a Generator: 15 Steps

-

Step 1: Define what “passing” looks like

Write down what you need the generator to do. Power a fridge and a few lights? Run a sump pump? Keep medical devices going? Testing isn’t one-size-fits-allyour “pass” depends on your real-world needs. A simple pass/fail definition keeps you from doing a random “it rumbled for a minute” test that proves nothing.

-

Step 2: Confirm your generator’s wattage and your critical loads

Make a short list of essentials and estimate the running watts and surge watts. Motors (fridges, pumps, some HVAC) often need a surge “kick” at startup. A generator can start fine and still fail under real load if you exceed its capacity.

Example: A refrigerator might run at a modest wattage but spike briefly at startup; a sump pump can surge higher than you’d guess. The test should reflect that reality.

-

Step 3: Choose a safe testing setup (location and ventilation)

This is non-negotiable: generators must be used outdoors in a well-ventilated area, away from doors, windows, and vents so exhaust can’t drift indoors. If your “test spot” could allow exhaust to enter a building, it’s not a test spotit’s a risk.

-

Step 4: Confirm you have working CO alarms (especially for portable generator plans)

CO alarms are cheap compared to everything else in this paragraph. If your generator plan is portable, confirm you have CO alarms in the home and that they work (per the device instructions). If you’re testing for storm readiness, alarms are part of readiness.

-

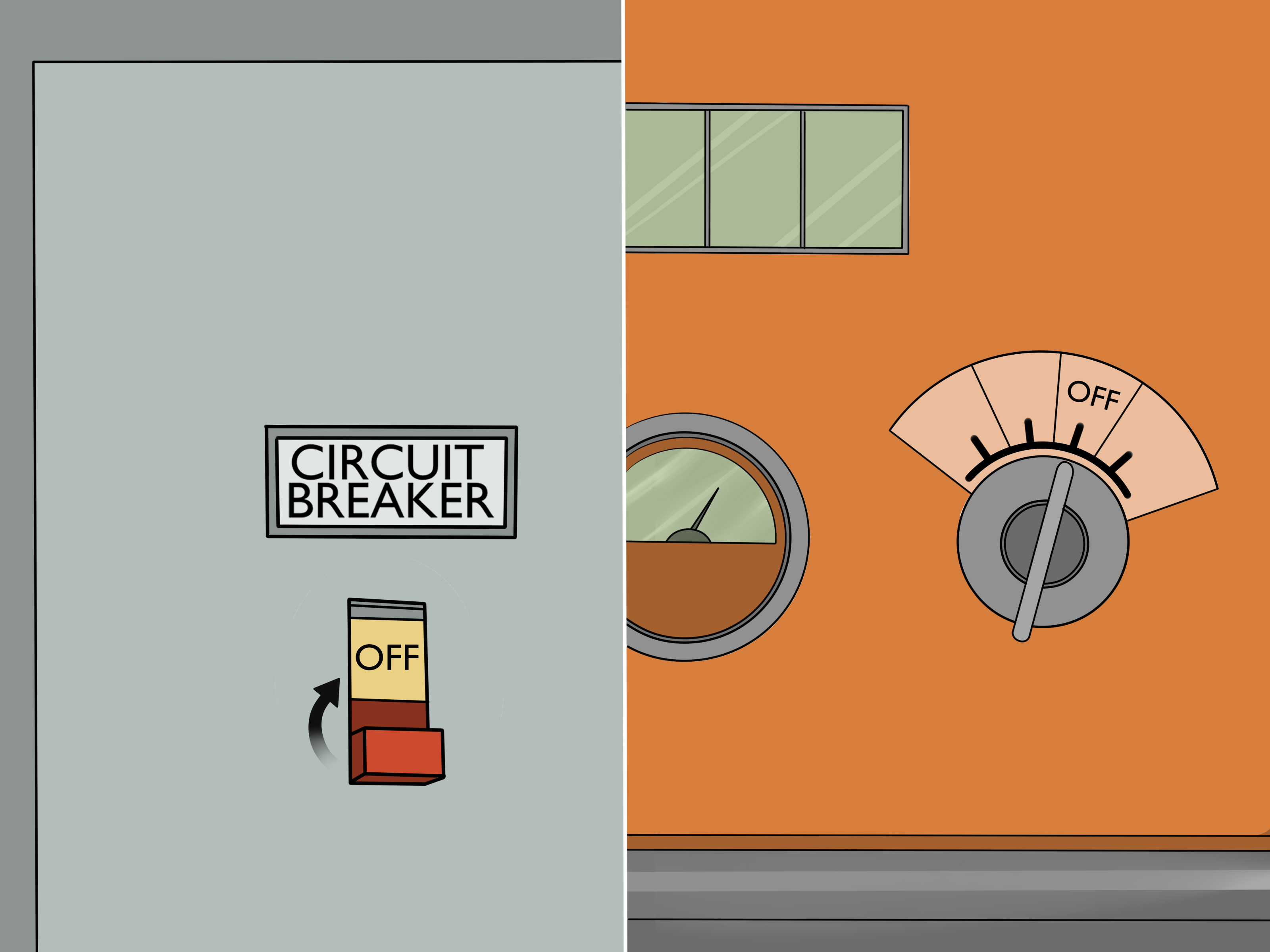

Step 5: Verify you’re not relying on “creative wiring”

If you want to power household circuits (not just plug appliances directly into the generator), use a properly installed transfer switch or interlockinstalled by a qualified electrician. This protects your home and prevents dangerous backfeeding.

If your plan involves “I saw a video where they…”stop and upgrade the plan. Testing a risky connection only proves you can be lucky twice.

-

Step 6: Do a calm, boring visual inspection

Before anything runs, inspect the unit: signs of leaks, corrosion, loose fasteners, cracked hoses, damaged wiring, blocked vents, or nests/debris. “Looks fine” is not a testso you’re looking for reasons it might not be fine.

Pro tip: If anything smells strongly of fuel or you see wet spots that shouldn’t be wet, that’s a “pause and call a pro” moment.

-

Step 7: Check maintenance basics (oil, filters, batteryper the manual)

Different generators have different maintenance schedules, so use your manual as the authority. In general, many units require periodic oil changes and filter inspections. Standby generators often rely on a battery that can quietly fail over time.

This step is less about doing a full service yourself and more about confirming nothing is overdue, missing, or obviously neglected.

-

Step 8: Confirm fuel readiness and fuel quality (without improvising)

Fuel issues are a top reason generators won’t start when needed. The safest approach is: use the fuel type the manufacturer specifies, store it safely and legally, and avoid old/stale fuel. If you’re unsure, a service shop can test/advise on fuel condition. The “mystery gas can from last summer” is not a strategy.

-

Step 9: Inspect cords, plugs, and protection devices

For portable generators powering appliances directly, you want heavy-duty, outdoor-rated extension cords in good conditionno cuts, no crushed sections, no loose prongs. For standby systems, confirm the visible external components (like conduit and enclosures) look intact and weatherworthy.

If you see damage, replace equipment rather than “testing anyway.” Testing damaged gear is like test-driving a car with bald tires in the rain: you might learn something, but not in the way you wanted.

-

Step 10: Make a simple test log (yes, really)

Write down the date, generator hours (if available), what you’re testing, and the result. Your future self will love you. Your technician will love you. And if something fails, you’ll know whether it’s a new problem or an old one with better marketing.

-

Step 11: Run the manufacturer-recommended “exercise” or test mode (standby generators)

Many standby generators perform an automatic exercise cycle on a schedule. Confirm that schedule is set, that the unit successfully completes its exercise, and that no warning lights or error codes are present afterward. If there are alerts, address them before the next outage.

-

Step 12: Plan a realistic load test (don’t guess under pressure)

A meaningful test includes loadbecause “it runs with nothing connected” isn’t the same as “it runs when life depends on it.” Decide what loads will be used for a test, and keep it realistic: essentials first, then add more only if your capacity allows.

For standby systems: A professional may use a load bank or test against building loads in a controlled way. The point is to verify performance without risking critical systems.

-

Step 13: Monitor for stability and red flags during the test

This is where observation matters more than bravery. During a properly supervised test (by a qualified adult/technician), watch for:

- Unusual surging or hunting (engine speed rising/falling repeatedly)

- Repeated breaker trips or fault indicators

- Burning smells, visible smoke (beyond normal brief startup behavior), or fuel odors

- Loads that flicker or behave erratically (a sign something isn’t stable)

If any red flag appears, stop the test safely and get professional help. A generator test is not the Olympics.

-

Step 14: Verify transfer behavior (only with proper equipment)

If your system includes an automatic transfer switch, the “test” isn’t only about the generator runningit’s about the system transferring power as designed. Transfer switch testing should be done according to the manufacturer’s guidance and often as part of professional maintenance, because it involves your home’s electrical system and utility connection rules.

-

Step 15: Do a post-test walkaround and schedule what’s next

After the test, re-check for leaks, new noises, warning lights, or anything that looks “different than before.” Update your log. If maintenance is due soon, schedule it nowdon’t wait until storm season, when everyone else has the same idea and service appointments get scarce.

What “Good” Looks Like After Testing

When your generator testing is done well, you should be able to say:

- “It’s safe to operate where we plan to operate it (ventilation and distance).”

- “We have CO alarms and a plan that doesn’t involve backfeeding.”

- “It can handle our essential loads reliably (not just ‘it turns on’).”

- “We know what maintenance is due and when.”

Common Generator Testing Mistakes (So You Can Avoid the Greatest Hits)

Mistake 1: Testing in a garage “with the door open”

CO can accumulate and drifttesting in an enclosed or semi-enclosed area is dangerous.

Mistake 2: Treating cords like an afterthought

Damaged cords can overheat or shock. If your cords look like they’ve survived three moves and a dog with opinions, replace them.

Mistake 3: Assuming “bigger is always better”

Oversizing can be expensive, but undersizing causes overload failures. The best size is the one that matches your real loads with a sensible cushion.

Mistake 4: Skipping the transfer switch conversation

If you want to power home circuits, get the correct equipment installed by a qualified electrician. This is about safety, not convenience.

How Often Should You Test a Generator?

- Standby generators: Many run an automatic weekly exercise; still plan periodic professional inspection and occasional load verification.

- Portable generators: Consider a periodic readiness check (especially before storm seasons). Focus on safety gear (CO alarms), cords, fuel strategy, and conditionthen do a supervised functional test that reflects your real loads.

- Critical use cases: If you rely on backup power for medical needs or a critical business process, treat testing and maintenance as a scheduled responsibilitynot a “when I remember” hobby.

Real-World Experiences: What People Learn After Testing (About )

People rarely remember their generator on a normal Tuesday. They remember it at 2:00 a.m. during a storm, when the house is dark, the phone battery is at 12%, and the refrigerator is quietly auditioning for “Warmest Fridge in America.” That’s why the most valuable part of generator testing isn’t the checklistit’s the lessons that show up in real life.

1) The “It Started Last Year” trap. One of the most common stories is a generator that worked perfectly the last time… and won’t start now. Often, the culprit is something unglamorous: a neglected battery on a standby unit, a clogged filter, or fuel that didn’t age gracefully. The lesson: testing isn’t proof of forever. It’s proof of today. That’s why a simple log and a routine matter more than heroic troubleshooting during a blackout.

2) The “Garage with the door open” myth. A lot of people think they’re being safe by placing a generator in the garage “but leaving it open.” Real-world incidents show that’s a dangerous assumption. Exhaust can collect and creep into living spaces. People who learn this lesson the easy way usually learn it while reading safety guidancepeople who learn it the hard way don’t get to write the story themselves. The takeaway: choose a truly outdoor, well-ventilated location and treat CO alarms as essential gear, not an optional accessory.

3) Extension cords become the surprise villain. Folks often test the generator and forget the weakest link: the cords. In real outages, cords get pinched in doors, draped across wet ground, or used in lengths that don’t match the load. The “test” looks fine until the cord heats up, trips protection, or causes flickering power. A better approach is to test the whole system: generator + cords + the actual devices you plan to run.

4) Overconfidence in wattage math. Many people do the math once and feel doneuntil they discover that startup surges are real and certain appliances don’t behave politely. A sump pump can surge. A fridge compressor can surge. If you test with the lights but not the pump, you didn’t test your true emergency scenario. The lesson: build a realistic load plan and practice it when the stakes are low.

5) Transfer switches are boringuntil they’re lifesaving. People who get a proper transfer switch installed tend to describe the same feeling: relief. In an outage, you’re already stressed. Eliminating wiring improvisation reduces panic and protects everyone involved, including utility workers. In real experiences, the best generator setups aren’t the flashiestthey’re the safest and simplest to operate.

6) The test that reveals “small” maintenance issues. Testing often exposes tiny problems before they become huge: a warning indicator, a loose connection, a vibration rattle, or a battery that’s fading. Catching those early turns an emergency failure into a scheduled repairexactly the kind of boring win you want.

7) The best moment to fix your plan is before you need it. People who test ahead of time get to calmly adjust: replace a cord, swap a battery, schedule service, reorganize what loads matter most, and decide where the generator will live safely. People who don’t test are forced to improvise in the dark. If generator ownership has a “secret,” that’s it: you’re not buying electricityyou’re buying preparedness. Testing is how you cash that check.

Conclusion

Testing a generator isn’t about proving you can “make it run.” It’s about proving your backup power plan is safe, realistic, and repeatable. Do the simple inspections, respect the hazards (especially CO and unsafe connections), and verify performance under the kinds of loads you’ll actually use. If anything feels uncertain or risky, let a qualified electrician or generator technician handle the hands-on testingbecause the best generator test is the one that keeps everyone safe and leaves you genuinely prepared for the next outage.