You don’t need a power plant, a hard hat, or a dramatic lightning storm to make electricity. With a coil of wire,

a magnet, and a little elbow grease, you can build a simple electric generator that proves a very real point:

motion + magnetism = usable power. (Not “run your fridge” powermore like “light an LED and feel like a wizard”

power.)

This guide walks you through a beginner-friendly generator you can build at home: a small “shake-style” linear

generator (similar in concept to a shake flashlight). It’s hands-on, inexpensive, and perfect for learning how

generators work without messing with dangerous voltages.

Quick Safety Note (Read This, Future Electrical Legend)

- Keep it low-voltage. This project is designed for tiny outputs (milliwatts to a few watts max).

- Never connect anything you build to a wall outlet or household wiring. Seriouslydon’t.

- Use adult supervision if you’ll solder, drill, cut, or work with strong magnets.

- Neodymium magnets can pinch hard and can affect certain medical devices. Handle with care.

- Don’t try charging lithium batteries from this. Stick to LEDs and capacitors for safety.

How a Generator Works (In Plain English)

Most generators run on the same basic idea discovered in the 1800s: a changing magnetic field near a conductor

(like copper wire) can induce a voltage, which can push electrons and create current. In practical terms, if you

move a magnet through a coil of wireor move a coil through a magnetic fieldyou can make electricity.

Big power plants spin massive coils and magnets using steam turbines, water flow, or wind. Your mini generator

uses you as the turbine. Congratulations: you are now renewable energy.

What You’ll Build

You’ll build a linear electromagnetic generator:

a coil of copper wire wrapped around a tube, with a magnet (or stack of magnets) sliding quickly through the

center. When the magnet moves, the magnetic field inside the coil changes, and voltage appears at the ends of

the wire. You’ll use that output to flash or light an LED.

This design is popular in classrooms and science fairs because it’s simple, visual, and teaches the core

principle of electromagnetic induction without complicated parts.

Tools and Materials

Core parts

- Magnet wire (enameled copper wire), about 26–30 AWG (thinner wire = more turns in less space)

- Strong magnets (neodymium discs work well); 2–6 discs you can stack

- Cardboard tube (paper towel tube) or plastic tube (smooth inside is better)

- LED (any standard 3–5 mm LED; a red LED usually lights more easily than blue/white)

- Tape (electrical tape or masking tape)

- Sandpaper or a small scraping tool (to remove enamel insulation from magnet wire ends)

Helpful extras (optional but nice)

- Multimeter (to measure voltage output)

- Heat-shrink tubing or extra tape (strain relief)

- Bridge rectifier (for converting AC to DC) or 4 small diodes

- Capacitor (e.g., 220–1000 µF) for smoothing flicker

- Supercapacitor (0.47–5F) if you want to store energy briefly (still not a phone charger!)

How to Make a Simple Electric Generator: 10 Steps

Step 1: Pick your tube and clean it up

Choose a tube that’s comfortable to holdpaper towel tubes are perfect. Make sure the inside is reasonably smooth

so the magnet can slide without getting stuck. If the tube is rough inside, consider using a plastic tube or

lining the inside with a smooth layer of paper.

Step 2: Make a “magnet sled” that fits the tube

Stack your neodymium magnets together into a short column. Test-slide the stack through the tube. It should move

freely, not scrape the sides. If it’s too loose and wobbly, wrap a single thin layer of tape around the magnet

stack to reduce rattlingdon’t overdo it or it will jam.

Step 3: Mark the coil zone on the tube

Measure and mark a band around the center of the tube where your coil will goabout 1.5 to 3 inches long. Longer

coils can work, but a compact coil often produces a stronger effect for quick magnet motion.

Step 4: Start winding the coil (and commit to the vibe)

Leave about 6–8 inches of wire as a “lead” before the coil starts. Tape that lead to the tube so it doesn’t get

yanked. Now begin winding the magnet wire tightly around the marked zone. Keep the turns neat and snugimagine

you’re wrapping a tiny burrito of electricity.

Step 5: Add lots of turns (because turns are basically generator snacks)

Continue wrapping until you have at least 200–500 turns if you can. More turns generally means

more voltage, but also more resistance. For this simple build, “more turns” is usually your friend.

When you finish, leave another 6–8 inches of wire for the second lead and cut the wire.

Step 6: Lock the coil in place

Tape over the coil so it can’t unwind. Wrap tape around the coil a few times, but don’t crush it. Add strain

relief by taping the leads down to the tube on both sides of the coil so pulling on the wire won’t rip your

coil loose.

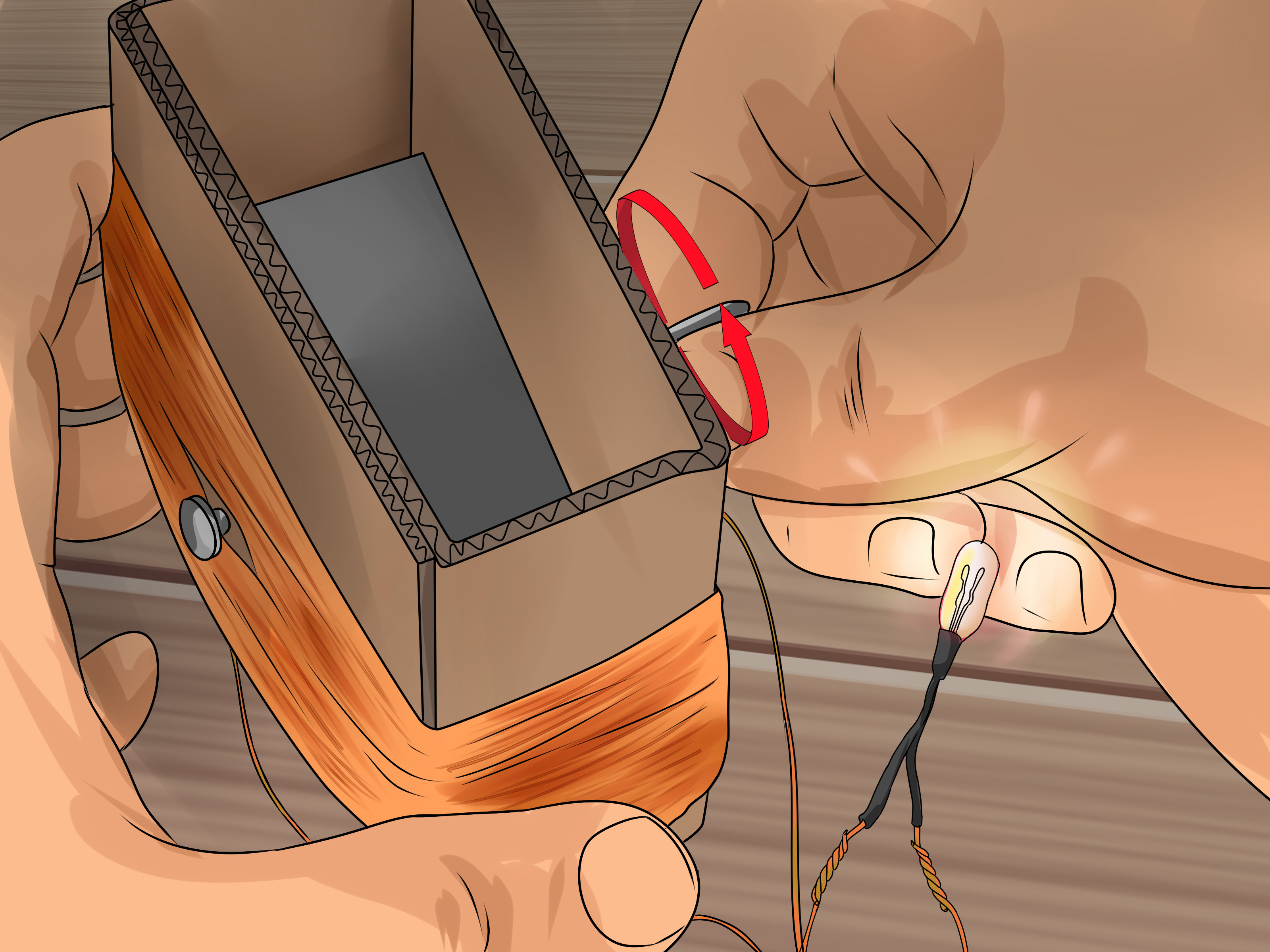

Step 7: Strip the enamel from the wire ends

Magnet wire is coated with enamel insulation, which is great for coils and terrible for making electrical

contact. Use sandpaper or a scraper to remove enamel from the last 1–2 cm of each lead until shiny copper

is visible. If you skip this step, your LED will stare at you with the cold indifference of a housecat.

Step 8: Connect the LED (and don’t panic if it doesn’t light)

Twist one stripped wire lead to one LED leg, and the other lead to the other LED leg. The generator produces

AC-like pulses (the polarity changes as the magnet moves), so the LED may only light on certain shakes or in one

direction. If you see flashes: you’re winning.

Tip: If it flashes only sometimes, reverse the LED legs or try a different shaking direction.

This behavior is normal.

Step 9: Add end stops so the magnet doesn’t escape like it owes rent

Put a soft “stopper” at each end of the tubewadded paper, foam, or a folded tissue taped in place. This keeps

the magnet stack from slamming into the ends, reducing noise and protecting the tube (and your sanity).

Step 10: Test, tweak, and measure your output

Slide the magnet stack through the tube quickly. Try a sharp up-and-down motion. The LED should flash; with the

right setup, it may glow faintly during vigorous shaking. If you have a multimeter, measure the voltage across

the coil leads while shaking. You’ll often see spikes that jump around depending on speed and magnet strength.

Now tweak one variable at a time: more magnet strength (stack magnets), more coil turns, a tighter coil, a

smoother tube, or faster motion.

Optional Upgrades (More Power, Less Flicker)

Upgrade 1: Add a bridge rectifier (AC to DC)

Your coil output is alternating (or at least polarity-changing pulses). If you want a steadier DC output, add a

bridge rectifier. That’s a simple circuit (often a single component) that flips the negative half-cycles so the

output stays one polarity. It’s like telling the electrons, “We only go this way in this household.”

Note: Diodes cause a small voltage drop. For tiny generators, consider diodes designed for low

voltage or accept that you may need stronger shaking to see results.

Upgrade 2: Add a capacitor to smooth the flashes

If your LED is flickering like it’s in a spooky movie, connect a capacitor after the rectifier (observing

polarity if it’s an electrolytic capacitor). The capacitor stores a little energy between shakes, helping the LED

look more stable.

Upgrade 3: Use the “science fair method” to boost output

- More turns (within reason): increases voltage potential.

- Stronger magnetic field: stack magnets or use larger magnets that still slide freely.

- Faster change: move the magnet faster; abrupt motion often beats slow motion.

- Lower resistance: keep lead wires short, avoid loose coil turns, and make clean connections.

Troubleshooting (When the LED Refuses to Celebrate With You)

The LED never lights

- Double-check that you removed enamel from the wire ends (shiny copper = good).

- Make sure the magnet stack is strong enough and actually moving through the coil region.

- Try a red LED (often easier to light) or test the LED with a known small battery (briefly).

- Increase coil turns or tighten the coil so it sits close to the magnet path.

The LED flashes only in one direction

That’s normal because polarity changes with motion direction. A bridge rectifier fixes this by making both

directions produce usable DC.

It lights, but it’s very dim

- Add more coil turns.

- Stack more magnets (as long as they still slide freely).

- Reduce friction inside the tube.

- Improve connections (twists can be lossy; soldering helps with adult supervision).

What Can You Power With This?

Let’s set expectations like responsible adults (even if we’re holding a tube full of magnets and joy).

A simple generator like this can typically:

- Flash or light a single LED

- Charge a capacitor for short bursts of light

- Power small ultra-low-power circuits briefly (with careful design)

It will not realistically charge your phone by hand without a much more advanced build (gearing,

regulation, storage, and a lot more mechanical power). Your phone is basically a tiny diva that demands stable

voltage and current. Your coil generator is more of an enthusiastic street performer.

FAQ

Is this the same idea used in power plants?

Yesthe scale is different, but the physics is the same. Large generators rotate coils and magnets continuously

using turbines driven by steam, water, wind, or combustion. Your hand provides the mechanical energy here.

Why does shaking faster help?

Because the voltage depends on how quickly the magnetic field through the coil changes. Faster motion usually

means a faster change in magnetic flux, which boosts the induced voltage.

Can I use a motor instead of building a coil?

You can. Many DC motors can act like generators when you spin them. That’s an even simpler way to demonstrate

energy conversion. But winding a coil and moving magnets gives you a clearer look at the fundamental induction

principle.

Real-World Experiences and Lessons (Extra )

People who try this project for the first time tend to learn two big lessons immediately: (1) electricity is not

magicit’s physics you can poke with your handsand (2) tiny generators are picky, like cats choosing a sunbeam.

The most common “aha!” moment happens when someone shakes the tube gently and gets nothing, then gives it one

confident snap and suddenly the LED blinks. That blink is a tiny victory parade for Faraday’s law.

In classrooms and maker spaces, builders often start by blaming the LED: “Maybe it’s broken.” Then they test the

LED and it works. Next suspect: the magnet. “Maybe it’s not strong enough.” Sometimes that’s true, but more often

the real culprit is the invisible villain: enamel insulation. Magnet wire looks like copper, but

it’s basically copper wearing a clear raincoat. If you don’t sand that coating off, your “connection” is more of

a polite handshake through a window.

Another frequent experience is discovering how much friction matters. A magnet that slides smoothly produces

consistent pulses; a magnet that catches and stutters produces sadness. Builders usually fix this by adjusting

fitadding a thin tape wrap to reduce wobble without creating dragor by switching to a smoother tube. That’s also

when people realize engineering is often about details that sound boring until they ruin your day.

Once the LED is flashing reliably, the next wave of curiosity hits: “How do I make it brighter?” This is where

experimentation becomes the real hobby. Some people add more turns, carefully winding layer after layer until

their coil looks like a tiny cinnamon roll. Others stack magnets and discover that “stronger” isn’t always better

if it makes the magnet scrape the sides and slow down. You’ll also notice that different LEDs behave differently.

A red LED might glow sooner, while a blue or white LED may demand more voltage before it does anything at all.

The most satisfying “upgrade moment” is adding a bridge rectifier and capacitor. The LED stops acting like a

strobe light at a dance club and starts looking more steadystill not perfect, but noticeably smoother. Builders

often describe it as the project going from “science demo” to “tiny device.” It feels more real because you can

shake, pause, shake again, and the light doesn’t instantly give up.

Finally, many people walk away with a deeper appreciation for everyday electricity. After you feel how much work

it takes to produce even a little light by hand, the idea that entire cities run on generators becomes more

impressive. This project doesn’t just teach how to make a simple electric generatorit teaches why engineers care

so much about efficiency, materials, and clever design. Also, it teaches that your arm is not, in fact, a

perpetual motion machine. (Science is cruel, but fair.)