Your car should accelerate like a confident adultsmooth, quiet, and not shaking its keys like a toddler who found the snack drawer.

If you’re hearing a rattle when you press the gas, you’re not alone. “Rattling” is the automotive equivalent of saying “my knee feels weird”:

it could be nothing… or it could be a sign your wallet is about to do a backflip.

The good news: most acceleration rattles come from a handful of predictable placesexhaust heat shields, loose brackets, worn mounts, spark knock,

suspension bits, or (occasionally) something dramatic and expensive. This guide helps you sort the sound, narrow the cause,

and choose the right fixwithout guessing, panicking, or turning your stereo up to “denial.”

First: What Kind of “Rattle” Are We Talking About?

Different problems make different noises. Before you crawl under the car or assume the worst, try to describe what you hear.

The better your “sound story,” the faster you’ll diagnose it.

1) Tinny, metallic buzz (often at specific RPM)

Think: a soda can vibrating on a washing machine. This is classic heat shield or thin metal bracket territory.

It often appears at a narrow RPM range (say, 1,800–2,400 rpm), then disappears like it never happened.

2) “Marbles in a coffee can” (from the engine, under load)

That sharp, rapid rattle during accelerationespecially going uphillmay be engine knock (also called pinging/detonation).

It’s combustion happening at the wrong time, and it’s not a sound to “live with.”

3) Clunk-thunk on takeoff or gear changes

A heavier knock or clunk when you first apply throttle can point to motor mounts, driveline play,

or CV axle issuesparts that are supposed to hold things steady while torque does its chaotic little dance.

4) Rattle plus vibration, plus “it feels worse at speed”

Now you’re thinking exhaust hangers, suspension links, wheel bearings,

or other rotating/loaded components. The “feel” matters as much as the sound.

Quick Safety Check: When to Stop Driving

Some rattles are annoying. Others are “pull over and call it” urgent. Don’t keep driving if you notice any of these:

- Oil pressure light, overheating warning, or a flashing check-engine light

- Loud knocking that rises quickly with RPM

- Loss of power, stalling, or severe shaking under acceleration

- Exhaust fumes in the cabin (especially with headaches or dizziness)

- Grinding or metal-on-metal sounds

The Most Common Causes (and What the Fix Usually Looks Like)

Loose or damaged exhaust heat shield

Heat shields are thin metal guards that protect the floor, fuel lines, and nearby components from exhaust heat. Over time,

bolts rust, spot welds crack, and the shield starts vibratingoften most noticeable at startup and when accelerating.

Typical clues: tinny rattle under the car, worse at certain RPM, sometimes disappears at steady cruise.

Fix: reattach with new hardware, clamps, or replacement shield. In some cases, a shop can secure it quickly.

Don’t just remove it and forget itheat shields exist for a reason (read: preventing melted stuff and rare-but-real fire risks).

Loose exhaust bracket, hanger, or leaking exhaust joint

The exhaust system is long, heavy, and constantly vibratingso hangers and brackets take a beating.

A broken hanger can let pipes or the muffler tap the underbody under load. Leaks can also create odd rattles, pops, or vibrations when you accelerate.

Typical clues: rattle from the middle/rear, changes when you hit bumps, sometimes louder with throttle.

Fix: replace hangers/brackets, repair leaks, tighten clamps, replace gaskets or damaged sections. Exhaust work is usually straightforward

once the culprit is found.

Catalytic converter rattle (internal substrate breaking)

Inside a catalytic converter is a honeycomb “brick.” When it breaks apart, it can rattle like a box of small rocksoften noticeable at idle

and during acceleration. A failing converter may also come with power loss or emissions-related warnings.

Typical clues: rattle from the exhaust area, sometimes combined with sluggish acceleration or a check-engine light.

Fix: diagnosis first (because heat shields can mimic this sound), then replacement if the converter is failing.

If you replace it, make sure the underlying cause is addressed too (misfires, rich running, oil burning), or the new converter may suffer the same fate.

Engine knock (pinging/detonation) under acceleration

Engine knock is rapid, sharp rattling caused by abnormal combustion. Common triggers include using fuel with too low an octane rating for your engine,

carbon buildup creating hot spots, incorrect ignition timing (older vehicles), overheating, failing knock sensor inputs, or spark plug problems.

Typical clues: marbles-in-a-can sound from the engine, worse uphill or when you press the gas harder, often improves if you ease off.

Fix ideas that actually make sense:

- Use the octane grade recommended in your owner’s manual (especially important for turbocharged/high-compression engines).

- Address overheating (coolant level, radiator fans, thermostat, clogged radiator).

- Replace worn spark plugs and inspect ignition components.

- Scan for codes; a knock sensor or fuel/air issue may show up indirectly.

- If carbon buildup is suspected, consider professional cleaning/decarbonizing and correct maintenance intervals going forward.

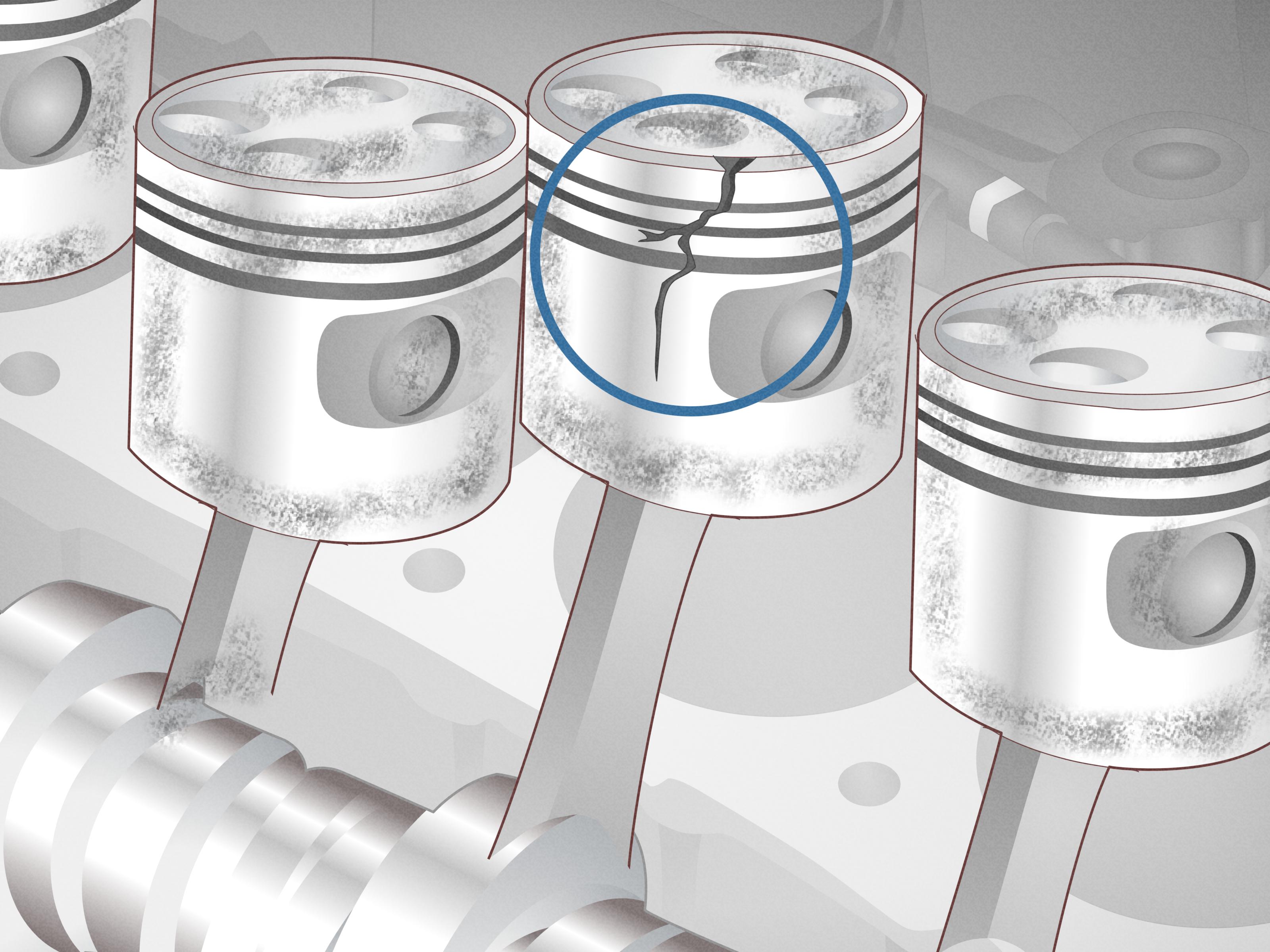

Why you shouldn’t ignore it: persistent detonation can damage pistons, rings, and bearings. That’s the kind of “rattle” that

turns into a “rebuild.”

Bad motor mounts (or transmission mounts)

Motor mounts are the rubber-and-metal cushions that keep the engine from doing the Macarena under torque.

When mounts crack or separate, the engine can shift more than it shouldcausing clunks, thumps, or rattles during acceleration and shifting.

Typical clues: clunk on takeoff, noticeable engine movement, vibration at idle, or a “bump” feeling when shifting between Drive and Reverse.

Fix: replace the failed mount(s). It’s a common repair, and it can transform how the car feelslike switching from wobbly sneakers

to actual shoes.

CV axle / CV joint wear (front-wheel drive & many AWD vehicles)

CV joints allow the axle to transmit power while the suspension moves and the wheels steer. When they wear,

they can click or clunkespecially during acceleration while turning.

Typical clues: clicking in turns, clunk during acceleration, torn CV boot with grease splatter near the wheel.

Fix: replace the axle assembly or CV joint (depending on the vehicle and parts availability). Don’t wait too long;

a failed CV joint can leave you stranded.

Suspension or steering components (sway bar links, strut mounts, ball joints)

Some “acceleration rattles” aren’t engine-related at all. When you accelerate, weight shifts rearward; when you brake, it shifts forward.

Worn links, mounts, or ball joints can clunk as the suspension loads and unloads.

Typical clues: clunk over bumps, noise during low-speed turns, rattling on rough roads, wandering steering, uneven tire wear.

Fix: inspection and replacement of worn parts (often sway bar links or strut mounts are common culprits).

Suspension work affects safetyso a proper diagnosis is worth it.

Serpentine belt tensioner, pulleys, or accessory issues

Under the hood, a worn belt tensioner or pulley can create rattles, chirps, or clicking noisessometimes more noticeable as RPM rises.

This can mimic “engine rattling” even though the engine itself is fine.

Typical clues: noise from the front of the engine, changes with RPM, may be worse at cold start or when accessories kick on.

Fix: inspect belt condition, tensioner operation, and pulleys. Replace the faulty component(s) before a belt failure leaves you

without charging or cooling.

Timing chain or valve train noise

Some engines develop timing chain rattle or valvetrain ticking that becomes more obvious with acceleration, especially on cold starts.

This is not as common as heat shields or mounts, but it’s important because internal engine wear can escalate.

Typical clues: rattle at startup, noise from the top/front of the engine, may quiet when warm (or may not).

Fix: professional diagnosis. If timing components are worn, repairs can be significant, but ignoring it can be catastrophic.

Transmission-related noises (especially if shifting feels off)

A buzz, whine, or clunk during accelerationpaired with delayed shifting, slipping, or harsh engagementcan indicate transmission issues or low fluid.

Not every transmission noise is a death sentence, but it is a “don’t procrastinate” situation.

Fix: check for leaks, confirm correct fluid level (using the correct procedure for your vehicle), and get a diagnostic if symptoms persist.

A Simple DIY Diagnosis Game Plan (No Crystal Ball Required)

You don’t need a full tool truck to make progress. You need a calm approach, a few observations, and a willingness to admit when something is beyond DIY.

Step 1: Note the “when”

- Only when accelerating? (load-related: mounts, knock, exhaust movement)

- Only at a certain RPM? (heat shield resonance is famous for this)

- Only when turning? (CV joint suspects)

- Only over bumps? (suspension links, strut mounts, loose exhaust hangers)

- Cold start vs warm? (timing chain rattle, heat shield expansion, thick fluids)

Step 2: Do the “free fixes” first

Before you blame the drivetrain, remove the obvious: empty the door pockets, center console, glove box, trunk/cargo area,

and check for a loose spare tire or jack kit. Yes, this happens constantly. No, nobody brags about it.

Step 3: Quick visual checks (engine bay)

- Look for loose plastic covers, missing fasteners, or a dangling splash shield.

- Inspect the serpentine belt for cracking and the tensioner for wobble.

- Check for obvious engine movement (excessive rocking can indicate mount issues).

Step 4: Quick visual checks (under the carsafely)

If you safely lift the vehicle (level ground, proper jack points, jack standsno exceptions),

look for loose heat shields, broken exhaust hangers, or shiny “rub marks” where the exhaust is contacting the body.

A gentle tap with a rubber mallet (or careful hand pressure when cool) can reproduce a heat shield rattle.

Step 5: Use your phone like a mechanic’s notebook

Record a short video with audio: one clip at idle, one while gently revving in Park, and one during a light drive.

Note speed, RPM, and whether the sound changes when you slightly lift off the throttle.

This helps a shop diagnose fasterand helps you avoid the dreaded “could not duplicate concern.”

Step 6: Scan for codes if engine knock is suspected

If the sound seems like pinging/detonation, don’t guess. Many auto parts stores will scan OBD-II codes for free,

and a basic scanner is inexpensive. Codes won’t always point directly to “rattle,” but they can reveal misfires,

knock sensor issues, lean conditions, or other problems that create knock under load.

Fix or Shop? A Practical “What Should I Do Next?” Guide

| What you notice | Most likely suspects | DIY-friendly? | Urgency |

|---|---|---|---|

| Tinny rattle at certain RPM | Heat shield, loose bracket | Often yes | Low–Medium |

| Rattle + exhaust smell or louder exhaust note | Exhaust leak, broken hanger | Sometimes | Medium |

| “Marbles” sound under load, uphill | Engine knock (fuel, plugs, carbon, overheating) | Some checks yes | High |

| Clunk on takeoff / shifting | Motor/trans mounts, driveline play | Inspection maybe | Medium–High |

| Clicking while turning + accelerating | CV joint/axle | Sometimes | Medium–High |

| Rattle over bumps | Sway bar links, strut mounts, suspension hardware | Inspection maybe | Medium |

| Rattle from exhaust area at idle and accel | Catalytic converter substrate, heat shield | Diagnosis mostly | Medium–High |

How to Prevent Acceleration Rattles (Because Peace and Quiet Is a Lifestyle)

- Use the recommended fuel: If your engine calls for premium, it’s not being dramaticit’s being specific.

- Stay on top of maintenance: Spark plugs, oil changes, and cooling system service prevent the kind of issues that become expensive noises.

- Inspect exhaust hardware occasionally: Rust and vibration are a team sport.

- Don’t ignore small clunks: Worn mounts and suspension links often start subtle and get louder with time.

- Avoid pothole “collections”: Suspension parts don’t enjoy surprise craters, no matter how adventurous you are.

Conclusion: Turn the Rattle Into a Plan

A car rattling when you accelerate can be as simple as a loose heat shield or as serious as engine knock.

The trick is to stop treating “rattle” like one problem and start treating it like a category.

Identify the sound, note when it happens, rule out the easy stuff, then inspect the most common culprits in a logical order.

If the noise is sharp and engine-related under load, prioritize itdetonation is not a “later” problem.

If it’s tinny and RPM-specific, the fix may be quick. Either way, your goal is the same:

get back to acceleration that sounds like progress, not percussion.

Real-World Experiences: 5 Rattles That Fooled People (and What They Really Were)

The funniest (and most frustrating) thing about acceleration rattles is how often they impersonate something worse.

Here are five common “this is definitely catastrophic” stories that turned out to be… less dramatic. Not always cheap,

but often more understandable once the mystery sound has a name.

1) The “my engine is falling out” rattle that was a heat shield

Drivers often report a metallic buzz that appears around a specific RPMsay, right when merging onto the highway.

The car feels normal, power is fine, and the noise disappears the moment you back off the throttle.

That pattern is practically a heat-shield signature. A thin sheet of metal can resonate like a cymbal when airflow,

vibration, and RPM line up just right. Many owners assume “transmission!” because it happens during acceleration,

but the fix is frequently as unglamorous as tightening fasteners or securing the shield with proper hardware.

The lesson: if the sound is tinny, repeatable at one RPM range, and not tied to bumps or steering,

check exhaust shields and brackets before you start doom-scrolling engine rebuild prices.

2) The rattle that sounded like a jar of coins: catalytic converter vs. the “fake-out” shield

A converter with broken internal material can truly sound like rocks in a metal box, and it may rattle at idle and under throttle.

But here’s the twist: a loose converter heat shield can make a nearly identical noise.

This is where careful inspection matters. A shop may tap the exhaust components (when cool) to reproduce the sound,

then isolate whether it’s external (shield) or internal (substrate).

The lesson: treat “rocks under the car” as a diagnosis clue, not a verdict. Confirm before replacing expensive parts.

3) The “my car hates regular gas” moment (a.k.a. engine knock under load)

Some drivers notice a sharp rattling only when climbing hills or accelerating hardespecially on hot days.

They might swear it’s coming from under the car, but it’s actually combustion knock. Switching to the correct octane

can reduce or eliminate it in engines that require higher octane, while other cases point to carbon deposits,

tired spark plugs, or cooling issues. This is the rattle that people try to “drive around” by being gentler on the throttle.

That might reduce the sound, but it doesn’t address the cause.

The lesson: if the rattle is strongest under load and eases when you lift slightly, put engine knock high on your list and investigate promptly.

4) The clunk on takeoff that was “just” a motor mount (and why it felt so dramatic)

A worn motor mount can make the whole car feel like it’s being nudged from underneath when you accelerate.

The engine shifts, contacts something it shouldn’t, or transfers vibration into the cabin.

Because it happens right as torque loads the drivetrain, it feels majoreven if the engine itself is healthy.

Many people chase suspension and transmission theories first, then are shocked by how much smoother the car feels once the mount is replaced.

The lesson: mounts don’t just reduce vibration; they control movement. When they fail, noises multiply.

5) The clicking rattle that only happened in turns: the CV joint giveaway

A classic scenario: quiet while cruising straight, but a clicking or clacking shows up when accelerating through a turn,

like leaving a parking lot or making a tight U-turn. CV joints are designed to flex and rotate under loadso when they wear,

they complain loudly during the exact moment they’re working hardest.

Sometimes the giveaway is visible: a torn boot and grease flung around the inside of the wheel.

The lesson: noises that change with steering angle are gold for diagnosis. If turning makes it worse, don’t ignore the axle/CV inspection.

In every case above, the winning move was the same: describe the sound, match it to a system, and test a theory before buying parts.

Rattles are annoyingbut they’re also your car’s way of saying “hey, I’d like attention before this becomes a personality.”